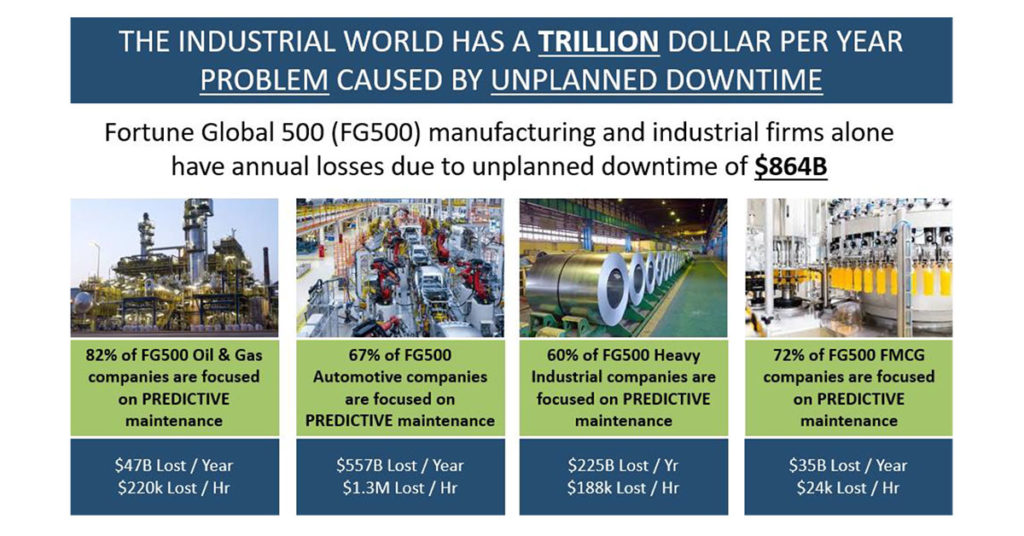

Maximize Uptime

Industry-leading 90,000 points of data across X, Y, Z axis at 20kHz in six seconds for detailed analysis, exceeding any other sensor on the market.

Improve Operations

Realize better business outcomes from your assets with improved efficiency, plant reliability, production rates, asset lifecycle, and profitability.

Reduce Mainteanance Costs

Pinpoint potential failures and anomalies before they happen and reduce maintenance costs including parts, labor, and mean time to repair.

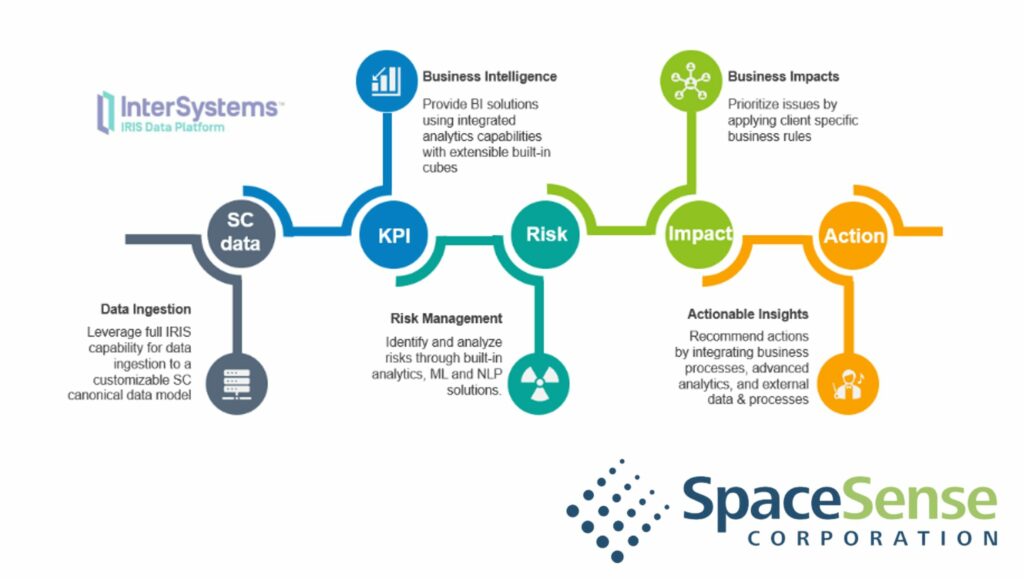

Harnessing the Power of Disruptive Digital Transformation Technology

SX3 technology significantly alters the way that manufacturers use sensors today. No one currently offers the depth, scope, speed and quality of vibration and pressure condition based monitoring and predicting of SX3 Technology.

We’re changing the way manufacturer see, use and benefit from wireless sensors. Find out how by speaking with an expert or requesting a trial of your own.

The Best in Sensing Technology

Lightning Speed Techology

Collects 90,000 bits of data within six seconds, two sweeps a day.

Immediate

Results

Provides immediate results with no trending required.

Extend the Life of

Your Plant

Includes long-lasting battery life for maximum performance.

Easy

Access

Flexible, and fits any surface and location with no wiring required.

Case Studies

SpaceSense Wireless Vibration Sensor Deployment

Don’t Make Decisions on “Quality and Production Planning” Based on Insufficient Data

Sense. More.

Simple to Deploy

Wireless, battery-powered true plug-and-play technology is quick and easy to install and configure and the square inch size is easily placed in hard-to-get-to locations.

Excellent ROI

Yield faster ROI by eliminating manual inspections, hand-held device expenses, streamlining parts management, and predicting and preventing catastrophic events.

Low Cost "Balance of Plant"

Cost effective and ease of use allows plant-wide monitoring of all assets, not just the mission critical capital expenditures.

Enhanced Data Diagnostics Capability

Advanced disruptive technology connects the physical and the digital world by tapping into disparate data sources that provide valuable and actionable insights into unseen patterns and trends.