Wireless Vibration Analytics vs Full Stack IIoT Solutions

Hi team – here are a few short takeaways from my experience in wireless vibration sensor solutions and analytics.

There are two types of analytic approaches in WIRELESS rotating vibration data collection.

1st Method

ISO – Trending = using calculated data RMS against the ISO green light, orange light / red light values and the progression of asset degradation.

- Unfortunately, if you are using a system that provides calculated data or may even purport to have the ability of full spectrum data you will find that these systems are excellent at alerting you to where you have fires across your asset classes and possibly the severity of them – they may even boast ML and AI, however the bottom line is they are a first stage approach to wireless monitoring.

- Do not expect this type of system to provide you with early warning of asset failure and if so what type of failure modes the asset is having.

- This simple solution will have a very limited effect on your overall production quality / time / cost or planning and supply chain management or your stock and resources management.

- This type of solution is siloed and will be a benefit from what you are doing now but your investment is short lived and will shortly be surpassed with full stack IIoT Solutions bring to the market complete Production control via fully managed IIoT solutions.

2nd Method

Full spectrum analysis through band failure clarification alarms to, velocity, acceleration, orders and time series dissemination large quantiles of analytical data.

In the first method ISO – this meets the requirements of low-cost sensors, that take data often at a very low sample rate. This conservers battery power in collection and transmission, while also reducing the error rates in transporting the data wirelessly.

The 2nd Method FSD – (Full Spectrum Data) – this is a very difficult solution to manage and requires varying levels of technology to ensure long battery life and QOS (Quality of Service) in data transmission.

- FSD method can provide from its data all the same ISO data and analytics but due to the large data high resolution capability, FSD allows a significant opportunity for very early fault detection.

- FSD data should be comparable with the handheld data collector’s data sampling at the same rate in excess of 12,000 samples per second/ per Axis XYZ (triaxial data collection) where data amplitude and resolution match the handheld dedicated unit.

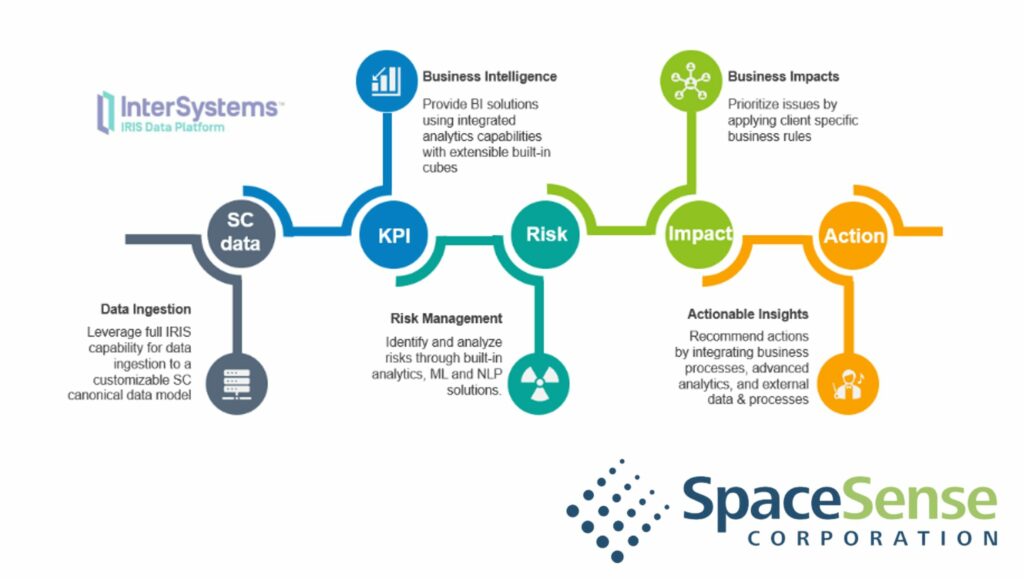

- FSD simulates your manual routes but every day instead of monthly or quarterly. Due to the decentralized data capability – FSD provides multiple opportunities through its full stack technology requirement and edge processing capability to enhance your complete supply chain, asset management and production systems, providing significant opportunities for actionable data across your organization. The impact of a full stack IIoT solution that can deliver Both ISO and FSD and can expand into all aspects of meta data from your OT/IT systems is the next generation of wireless edge IIoT solutions.

- Invest in full stack IIoT solutions as a base of your core digital transformation investment.

Call SpaceSenseSystems SX3™ for a consultation in how Wireless IIoT can benefit your existing production/ supply chain/ QTC (Quality Time Cost) across your organization.

Email us today at sales@spacesense.systems.