Don’t Make Decisions on “Quality and Production Planning” Based on Insufficient Data

Wondering why even with your periodic handheld data collectors– your ASSETS are still failing in advance of repair. Are you still in reactionary mode instead of Planning outages?

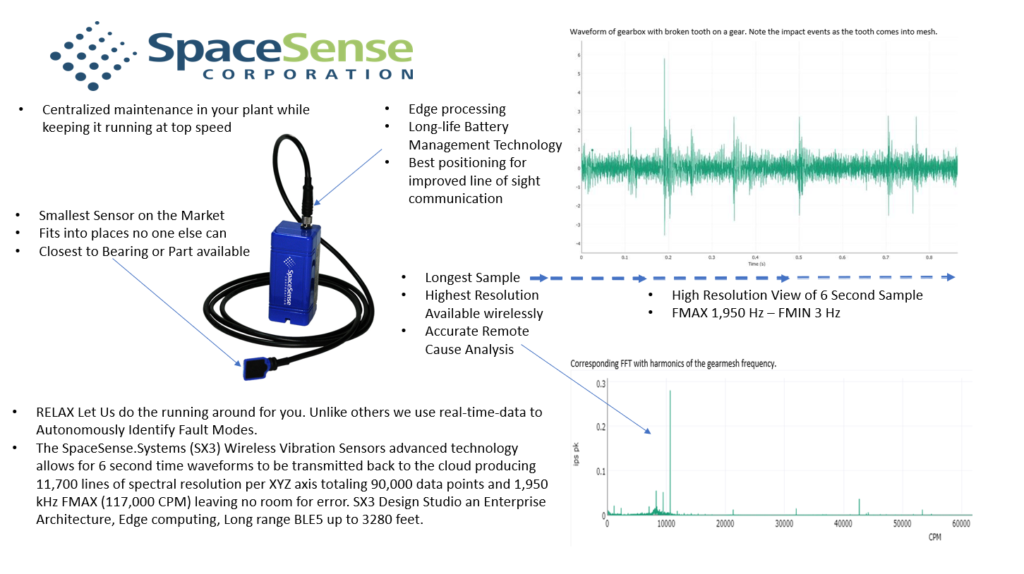

SpaceSense Autonomous Monitoring

Edge Processing; Long-life battery management technology; best positioning for improved line of sight communication; longest sample; highest resolution available wirelessly; real-time early fault detection.

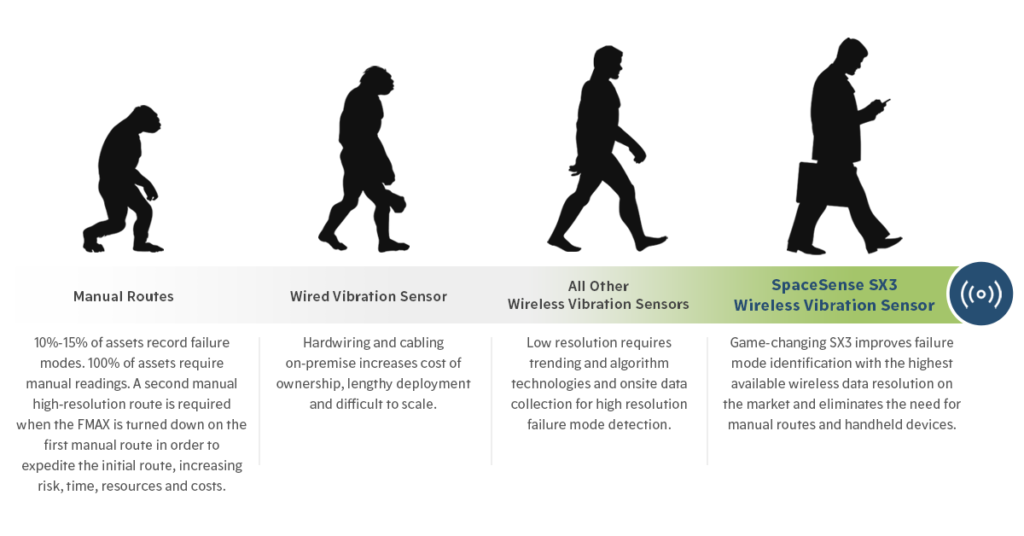

The Evolution of Collecting Vibration Data

Game-changing SX3 improves failure mode identification with the highest available wireless data resolution on the market and eliminates the need for manual routes and handheld devices.

Automation is unavoidable and high resolution has never been so critical

We take a Vibration and Temperature sample of a bearing turning at 36,000 RPM for six continuous, uninterrupted seconds using the highest quality Triaxle sensor collection 90,000 data records per X, Y, Z Axis at 20 kHz we then down sample to 5kHz. The data is then transmitted using BLE5 back to our Gateway.

Safely balancing human and machine efforts with SX3

There’s no question that the current pandemic has presented significant challenges for the industry and although we don’t have a cure, we are the next best thing for anybody that is tasked to take on site vibration readings.

Can Your Business Afford to Rely on Historical Trends to Find a Problem?

It was just a handful of years ago when manufacturers embraced a new trend of machine learning using sensors for condition monitoring to help them detect early faults and wear and tear of their assets so they could avoid unexpected and costly breakdowns.

Is Your Manufacturing Facility Prepared for Industry 4.0?

The next Industrial Revolution is upon us. You may have heard the terms Industry 4.0, factories of the future, or smart factories, but do you really know what that means? Put simply, Industry 4.0 is the modernization of manufacturing.

The Power of IIoT: Connecting the Dots Between Assets and Data

Now, on our fourth iteration of the Industrial revolution, Industry 4.0 continues to fulfill its mission to modernize manufacturing through increased efficiencies and sustainability by connecting the dots between a company’s physical assets and its data with the help of digital transformation through disruptive technologies.